The anchor chain job

Wenzel Marine is well known for quality service around marine engines. That Wenzel Marine is also the right contact for more exceptional maritime services, the company has recently proved while installing an anchor chain.

What had happened? On January 3 the container ship MS Faithful (name changed) was forced to anchor off Helgoland, because due to its draught and weather conditions it could not sail into the river Elbe to reach the Hamburg container terminal. When finally the OK came to enter port hydraulic problems of the windlass became noticeable. After several unsuccessful attempts to hoist the anchor, the captain decided probably correct to cut the chain and abandon the inserted length, including anchor. Now there were nine chain lengths (about 250 meters chain) plus anchor with a total weight of 200 tons lying on the ground.

The MS Faithful received permission by the class to exceptionally continue her journey without a second anchor, but only temporarily. Apart from the fact that a replacement is expensive, there is an obligation to recover such abandoned material or at least to try a salvage. Consequently, the shipping company responsible asked a salvage firm to retrieve the ground tackle. Since the position was known and the water at this point is not very deep, the contracted salvage company could do the job quickly. Now, chain and anchor were indeed out of the water but still not back aboard the MS Faithful; to bring them in properly and ready for operation on the container ship, however, was not for the salvage company.

With this part, the shipping company commissioned Wenzel Marine, a service provider well known to her as reliable. Wenzel Marine immediately began planning the action. The MS Faithful was due again in the port of Hamburg on March 20 at 6:00 am. At this time the barge with the salvaged anchor gear, a handful of technicians, a supervisor and tools had to be ready on the quay. Wenzel Marine arranged all this and the morning of March 20 actually missing was only the ship. She eventually arrived twelve hours late, so it became ultimately a night shift.

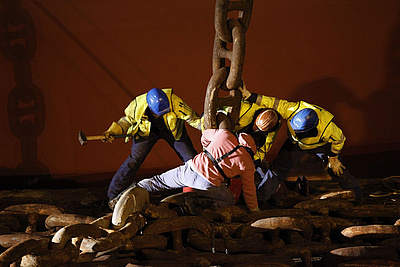

After about six hours of hard work the anchor chain was reconnected to the remaining length aboard the container ship and hauled in. However, the anchor did not fully catch up, because as it turned out, it was rotated 90 degrees and a swivel was not installed. Wenzel Marine´s engineer on site quickly had a solution: turn the anchor chain on the chain nut and / or the stopper. This, however, required a crane which was not available around midnight. So this task had been successfully completed the following day.

Of course during the entire execution of the work Wenzel Marine was in constant contact with the relevant Lloyd's Register EMEA Surveyor. The work was done in accordance and certified to the vessel.